Đồng Hồ Đo Lực Căng DX2S

Xuất sứ: Germany

Nhà cung cấp: HansSchmidt-Song Thanh Cong

Hãng sản xuất: Hans-Schmidt

10 Tension ranges available from 10 - 50 cN up to 5 - 20 daN

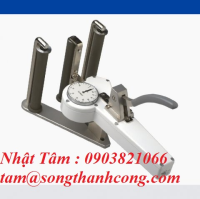

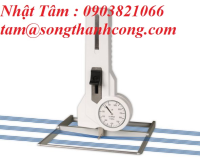

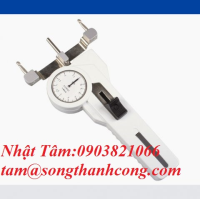

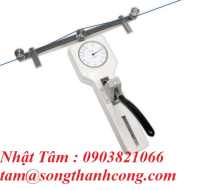

Stationary mechanical tension meter for measuring tensions of fibres, threads, wires, ribbons etc.

Universal tension meter for versatile applications in all sectors of industry

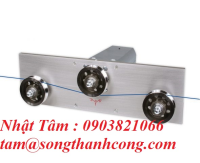

Special purpose models with big, small and tape rollers available

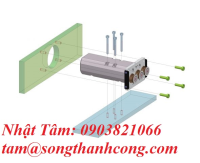

Note: Tension meter DX2S do not include a filament guide and material thickness compensator.

– the guide rollers

– the measured material

– the readings

| Model | Tension Range | Measuring Head Width* | SCHMIDT Calibration Material** |

| DX2S-50 | 10 – 50 cN | 54 mm | PA: 0.12 mm Ø |

| DX2S-120 | 20 – 120 cN | 54 mm | PA: 0.12 mm Ø |

| DX2S-200 | 20 – 200 cN | 54 mm | PA: 0.12 mm Ø |

| DX2S-400 | 20 – 400 cN | 54 mm | PA: 0.20 mm Ø |

| DX2S-1000 | 50 – 1000 cN | 54 mm | PA: 0.30 mm Ø |

| DX2S-2000 | 200 – 2000 cN | 116 mm | PA: 0.50 mm Ø |

| DX2S-5000 | 400 – 5000 cN | 116 mm | PA: 0.80 mm Ø |

| DX2S-8000 | 1000 – 8000 cN | 116 mm | PA: 1.00 mm Ø |

| DX2S-10K | 2.5 – 10 daN | 116 mm | PA: 1.00 mm Ø |

| DX2S-20K | 5 – 20 daN | 216 mm | PA: 1.50 mm Ø |

Other units of measure available – g or kg.

* Outer distance between outside guide rollers

** Suitable for 95 % of applications – PA = Polyamide Monofilament

Calibration to customized material:

If process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape, special calibration using customer supplied samples is recommended. For this purpose a material sample of about 5 m should be supplied.