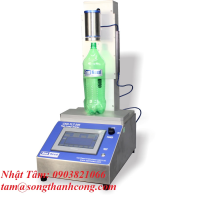

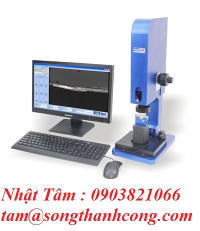

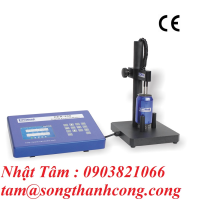

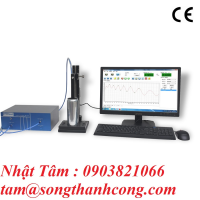

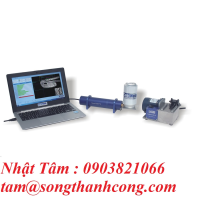

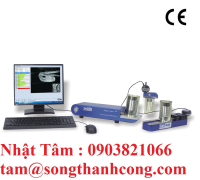

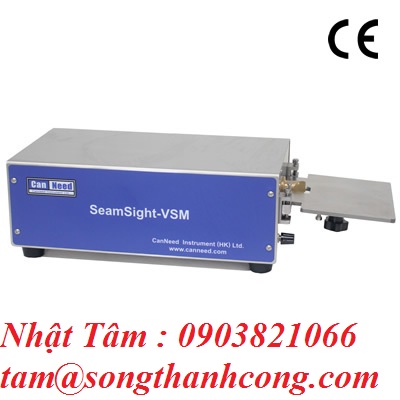

SeamSight VSM-6C VSM-6C Automatic Seam Monitor

Xuất sứ: Canneed

Nhà cung cấp: Canneed - Song Thanh Cong

Hãng sản xuất: Canneed

|

Usage |

|

|

VSM-6C Automatic Seam Monitor is a compact measuring system for quick and accurate |

|

|

Advantages |

|

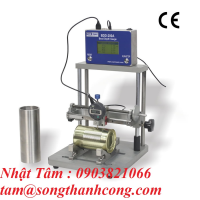

| Equip with Golden LensTM video capture device which ensured the high image definition; SPC compatible, use a data adapter to collect the data from Mitutoyo Digital Indicator (Actual Seam Thickness; Actual countersink) Resolution: 0.001mm Accuracy: 0.005mm Magnification factor: 60 X Line positioning magnification factor: 180 X Magnifier option enable users to magnify the testing image for a more accurate line positioning; The Anti-noise Seam Saw can be chosen, help protect your hearing; Report format can be customized, flexible for different report styles of different companies. 12 Measuring Items: Seam Length, Body Hook Length, End Hook Length, Overlap, Seam Gap, Overlap Rate, Body Hook Lapping Rate, End Hook Lapping Rate, On-screen Seam Thickness, Actual Seam Thickness, Actual countersink and Tightness; Software adopted data base management system, measurement results and images are saved in the data base, users can facilitate inquires; Users can review or re-measure the saved projects at any time; Graph chart statistic function, automatically analyze and compare the measurement results; Data can be exported as an Excel file; Predefine various qualification standards, can judge and warn automatically whether the results are qualified in every measure; Measurement results and label lines can be marked directly on the image, results will be also displayed in corresponding field on the screen; Seam image can be printed, stored, no need to retain the sample cans; Provided with calibration piece, calibrate at any time; Use the monochromatic source, make it much more durable. |

|

|

Technical Data |

|

|

Power supply : 220V/110V |

|