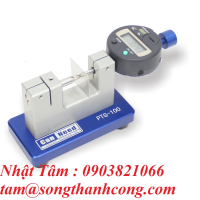

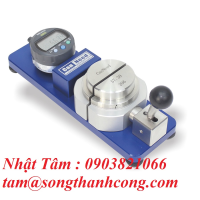

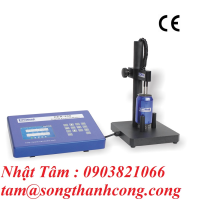

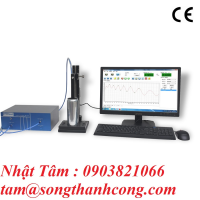

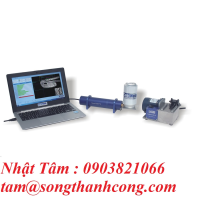

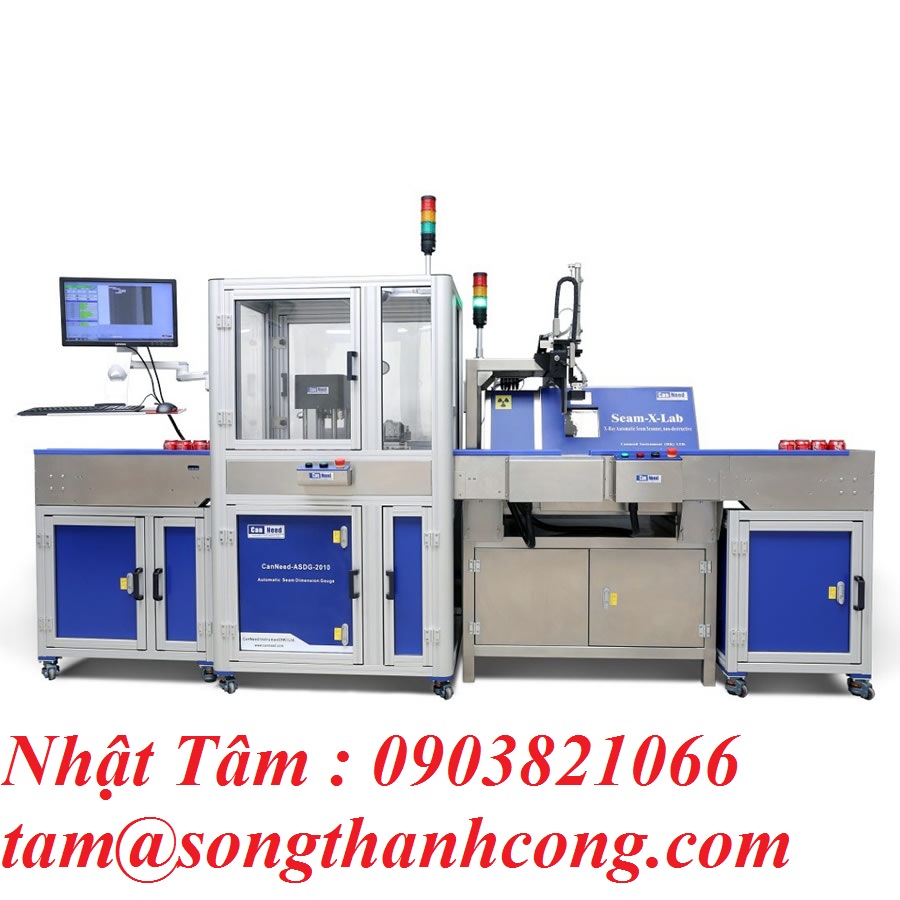

Seam-X®-Line CanNeed-Seam-X-Lab X-Ray Automatic Seam Scanner (Non-destructive)

Xuất sứ: HongKong

Nhà cung cấp: Canneed

Hãng sản xuất: Canneed

- Applications

Seam-X-Line Automatic Seam Scanner adopts non-destructive measurement method to measure the

seam quality, suitable for measuring the aluminium cans, steel cans , aluminium-iron composite cans and etc. If configured with the conveyor, it can achieve automatic sampling from the production line. It’s applicable for laboratory or producing department.

- Advantages

Non-destructive measurement, avoid wasting samples

Non-destructive measurement, avoid environmental pollution and save handling charges

High sampling frequency, reduce the isolation inferior

High sampling frequency, cost saving

Can track the chucks corresponding to the unqualified products

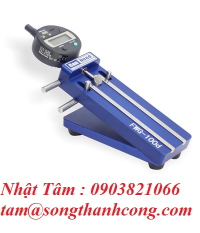

360-degree fully scan measurement

Can be suitable for various types of cans

Higher accuracy

Avoid manual measurement error

Durable

Accord with the worldwide safety standards

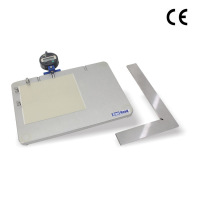

- Technical Parameter

Applicable for laboratory or producing department

Mode of sampling : Seam-X-Lab manual function; Seam-X-Line automatic function

Can open or close the door automatically

Auto measurement

Auto judgement

360-degree fully scan measurement, no blind spot detection

Measuring speed: need one minute for 1 can

Load: production time calculation for 22 hours one day; Measuring capacity: 22(h) X 60 (m) ÷ 1 (m) ≈1320 cans/per day.

It’s a stable and reliable equipment to the continuous detection.

Accuracy: 0.01mm;

Seam-X-Lab dimension :900*550*650 mm

Seam-X-Lab weight: 300kg;

Seam-X-Line dimension :3000*2000*2200mm

Seam-X-Line weight: 500kg