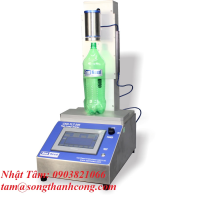

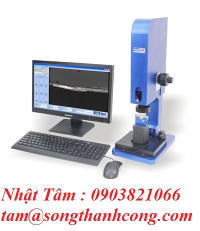

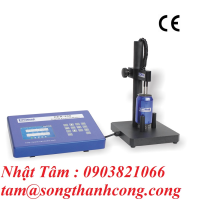

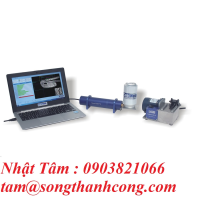

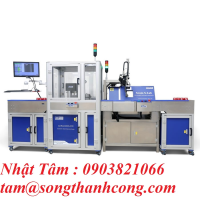

Seam-X®-SA-1000 Super Full Automatic Seam Monitor

Xuất sứ: HongKong

Nhà cung cấp: Canneed - Song Thanh Cong

Hãng sản xuất: Canneed

- Applications

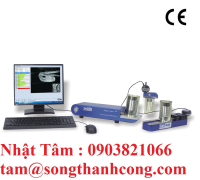

Configured with the projector and saw, Seam Sight-SA-1000 adopts completely new invention with features of auto sampling, auto cutting, auto measure, taking the place of the traditional manually cutting and measuring method, achieving integrated automatic measurement of the seam.

- Advantages

- Technical Parameter

1. Automatic sample input, Automatic can cutting, Automatic measurement;

2. Resolution 0.001mm;

3. Precision 0.005mm;

4. Magnification factor: 60 ×;

5. Line positioning magnification factor: 180 ×;

6. 12-holes sample input tool as standard issue;

7. Standard issues:for samples of 211 can, 202 cover,211 can, 206 cover; 330ml,500ml;other can types can be customized.

8. Auto collect seam thickness and countersink digital indicator data;

9. Ignore the interference of outer light sources;

10.SPC data output;

11.5 optional formulae for seaming overlapped rate calculating;

12.Customizable report format;

13.Hard metal alloy seam saws

14.Size: L1170XW730XH1070

15.Power Supply:220V/110V

16.Pneumatic supply: 0.4Mpa